Exactly How Ceramic Finishing Gives Lasting Protection Versus the Elements

Ceramic finishing has become an awesome remedy for safeguarding surface areas against diverse ecological challenges. By producing a resistant, chemically bound layer, it not just improves visual appeal yet also offers protection from UV rays, severe temperatures, and chemical spots. The hydrophobic qualities of ceramic finishing better add to its efficacy by pushing back water and decreasing dirt build-up. Comprehending the full scope of its benefits and just how it compares to conventional protective approaches increases vital inquiries regarding long-lasting maintenance and efficiency. What implications do these variables hold for various applications?

What Is Ceramic Layer?

Ceramic coating is an innovative safety solution that boosts the durability and appearance of surface areas, particularly in automobile applications. This ingenious technology is composed of a liquid polymer that chemically bonds with the factory paint of a lorry, developing a safety layer that is significantly more resilient than conventional wax or sealants.

Designed to provide resilient protection against ecological pollutants, ceramic finishings are immune to UV rays, chemical stains, and minor abrasions. This security helps preserve the car's visual charm over time, stopping oxidation and fading that can result from long term exposure to the elements.

Additionally, ceramic coatings are hydrophobic, indicating they fend off water and various other fluids, which aids in the avoidance of dust and crud buildup. This residential property not just makes cleansing less complicated yet also adds to keeping the car's shine.

Readily available in numerous formulas, ceramic coverings can accommodate different surface area materials, including glass and steel, expanding their applicability past simply automotive uses. Overall, the fostering of ceramic finishing innovation stands for a substantial advancement in surface defense, supplying an effective service for those seeking to preserve the honesty and look of their financial investments.

Just How Ceramic Coating Functions

The efficiency of ceramic layer depends on its special chemical composition and application process. Composed primarily of silica (SiO2) and various other sophisticated polymers, ceramic finishings produce a molecular bond with the surface area of the product they are related to, generally vehicle paint. This bond creates a semi-permanent layer that works as an obstacle against environmental pollutants.

When used, the covering goes through a curing process, which can take several hours to days, depending on ecological problems. As it remedies, the finishing hardens and ends up being hydrophobic, suggesting it wards off water and various other compounds.

Advantages of Ceramic Coating

Providing a wide variety of advantages, ceramic finishing acts as an exceptional option for surface defense. One of its key advantages is its resilience, supplying a durable obstacle against environmental impurities such as dirt, UV rays, and chemical direct exposure. This strength considerably extends the life-span of the surfaces it safeguards, lowering the requirement for frequent fixings or substitutes.

Furthermore, ceramic layers enhance aesthetics by imparting a glossy finish that preserves its shine with time. The hydrophobic properties of these finishes push back water, making it less complicated to clean surface areas and decreasing the buildup of grime. This self-cleaning particular not just conserves time but also improves the surface's overall appearance.

In addition, ceramic finishes offer resistance to scrapes and small abrasions, securing the stability of the underlying materials. This is particularly valuable for vehicle applications, where maintaining a beautiful exterior is crucial for resale value.

Contrasting Ceramic Finishing to Typical Techniques

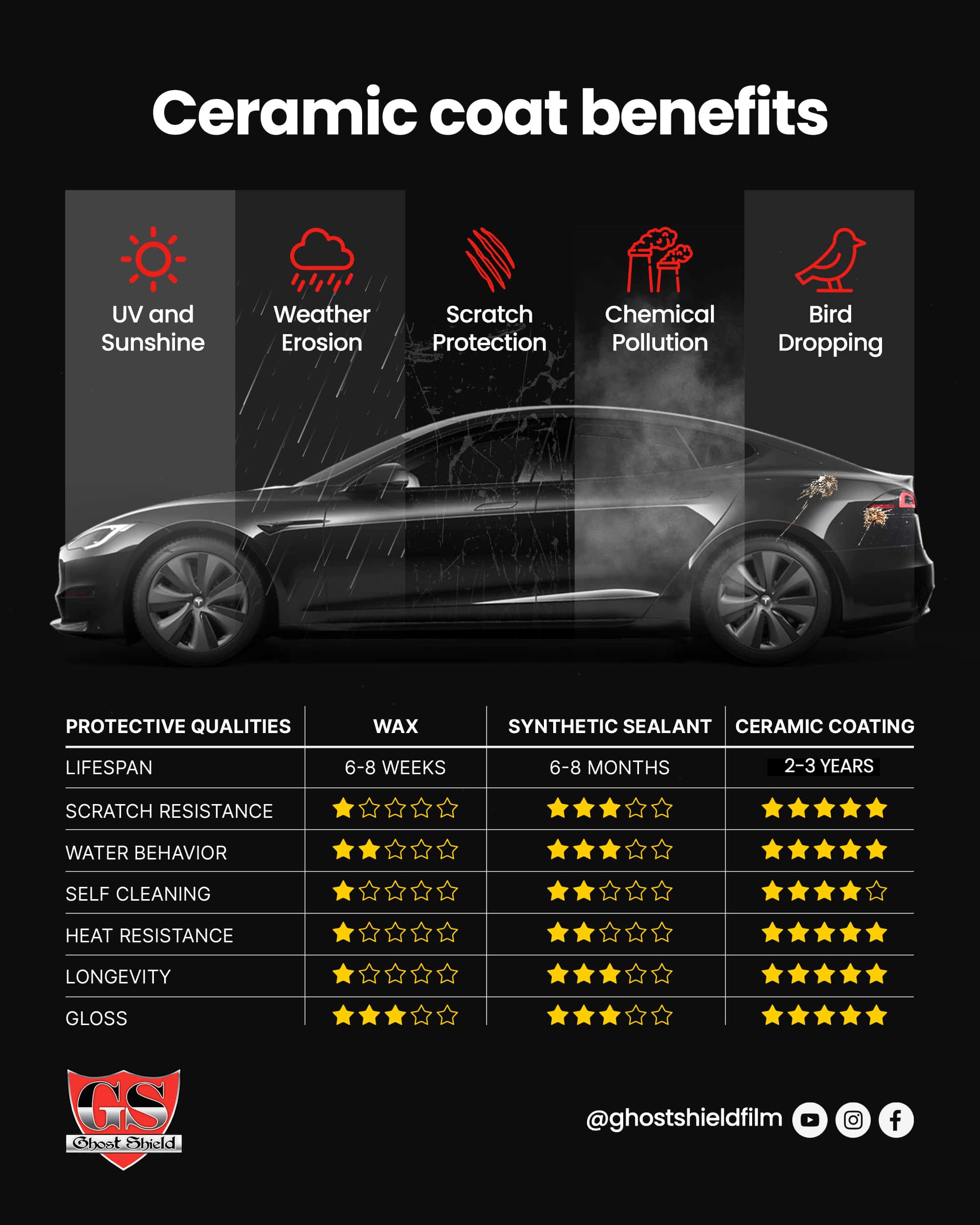

Often, individuals look for efficient remedies for surface area defense, triggering a contrast between typical methods and ceramic finishes such as wax or sealants. Typical alternatives like wax give a short-term layer of protection, generally lasting a couple of weeks to a number of months, depending upon ecological problems and car use. While wax can enhance shine and provide a barrier versus contaminants, its performance lessens rapidly, needing frequent reapplication.

In comparison, ceramic layers provide a more long lasting remedy, developing a strong, chemically bonded layer that can endure for several years. This lasting security significantly lowers the need for normal upkeep, enabling lorry owners to take pleasure in a consistently sleek appearance without the hassle of constant applications. Ceramic coatings are likewise much more immune to UV rays, chemicals, and physical abrasions, thus supplying premium defense versus the aspects.

While standard techniques may be more available and much less pricey at first, the longevity and efficiency of ceramic finishes present a compelling situation for those looking for thorough surface area security. Inevitably, the choice between conventional techniques and ceramic coatings depends on private priorities, such as time, budget plan, and desired level of security.

Upkeep Tips for Long Life

Comprehending the distinctions in between ceramic finishings and conventional approaches highlights the importance of proper maintenance to make best use of the longevity of ceramic coverings. Ceramic official site Coating Philadelphia. To guarantee the efficiency of ceramic finishings, regular care is necessary

First, always wash the covered surface with pH-balanced vehicle shampoos. Prevent abrasive products or extreme chemicals, as they can degrade the finishing. A mild hand clean with microfiber towels decreases the threat of scrapes.

Second, take into consideration using an upkeep spray designed especially for ceramic go to my blog layers. Ceramic Coating Philadelphia. This can boost hydrophobic homes and include a layer of protection, ensuring the covering continues to be effective over time

Third, stay clear of automated cars and truck washes that use brushes, as they can wear down the covering. Instead, choose touchless laundries or hand washing whenever feasible.

Finally, regular assessments for any kind of indications of damages or wear are vital. Resolving problems promptly can protect against much more comprehensive damages and maintain the finishing's honesty.

Final Thought

In summary, ceramic finish supplies a formidable option for securing surface areas from environmental difficulties. By contrasting it to conventional safety methods, the prevalence of ceramic finish ends up being apparent, making it a favored selection for durable surface security.

Recognizing just how ceramic coatings job is necessary in valuing their duty in surface defense.

Providing a plethora of benefits, ceramic layer serves as an extraordinary solution for surface area defense.Often, individuals look for reliable solutions for surface area protection, prompting a comparison between traditional techniques and ceramic finishes such as wax or sealants.In recap, discover this ceramic finish provides a powerful service for shielding surface areas from ecological difficulties. By comparing it to typical protective approaches, the superiority of ceramic finishing ends up being apparent, making it a preferred choice for resilient surface protection.